All Activity

- Today

-

Card types and how to get the head around?

sixwheeledbeast replied to Cieska's topic in General Security & Fire Queries

I suppose these are using proprietary Crypto1 format? If so maybe look at the documentation from the people that RE'd it? -

Card types and how to get the head around?

Cieska replied to Cieska's topic in General Security & Fire Queries

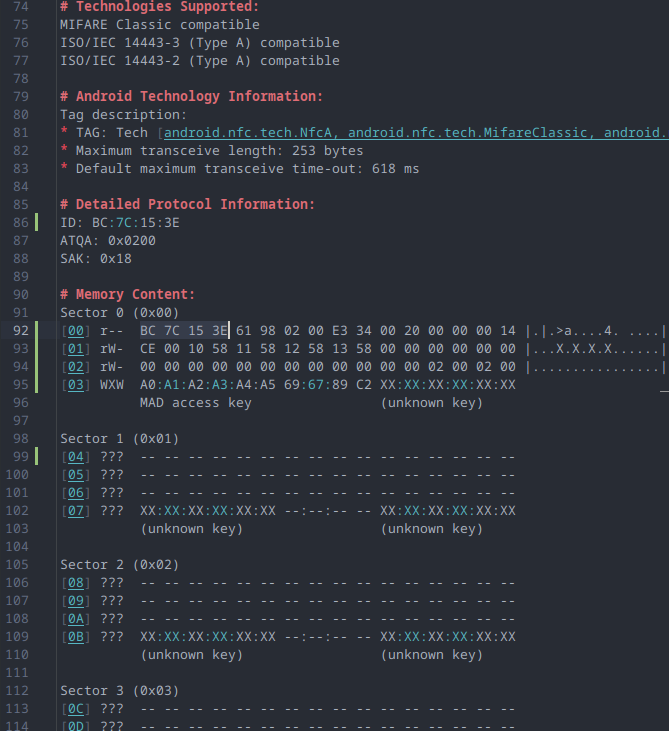

Hi, I know it's my old topic, but I have come back to it. The complication is to understand Card formats and how to read the data. At the moment for example: I have a Mifare Classic 4K card the ACS system by default reads the first 32bit which is the Card Serial Numer (CSN) The system is CEMsys AC2000 I know that I need to read different numbers, which are 8-digit number encoded in Sector-1 Block-2. To read CSN in the card definition setting field of the AC2000 Start position - 1 My question is why is this not start from position - 0 ? As computers read from zero first? As otherwise then all pern doesn't match when counting bits? Or I'm wrong here? Field length - 32 this is where I match my understanding against the CSN as I can read and match the first 32bits (4bytes) or hex value, in the screenshot line 92 of my text editor where I have selected the value. So, if the block length is 128bit (per line), then my interesting data starts at the 6th line which is per block number [05] (text editor line 100) as it starts counting blocks from [00] in the sector [00]. This should mean that it should start read my interesting data from 641bit and the Field length should be 24bits (as 8 digit number fits in 3bytes https://www.rapidtables.com/convert/number/decimal-to-hex.html ) another question here is - if the 8-digit number is encoded in hex or it's just the same number but in numbers only? In other words to say, how the read data is interpreted? Or if the reader reads the CSN number and displays hext then my number also, should be displayed as simple as this? We are talking about reading unencrypted data, as I was told I should read this dara simply when scanning the card. So I have many unknowns in my head, which is why it is totally confusing. I need some guidance or tips. or anything. The - Last week

-

bramvdh1 joined the community

-

Texecom Premier Elite - tamper alarm only when door contact is closed

ywu replied to ywu's topic in !!..DIY Installers..!!

I think that's resolved it. I've got an airgap of about an inch between sensor and magnet and it's enough for the alarm to say it's "secure" that the door is "closed". -

Texecom Premier Elite - tamper alarm only when door contact is closed

ywu replied to ywu's topic in !!..DIY Installers..!!

There was a gap of around 0.75 cm between the sensor and the magnet before. Maybe i'm putting them too close together and they need that air gap? I've now tried multiple orientations and it still triggers. -

I doubt if your messing with it yourself grade 3 equipment is required. But a grade 3 device is a high security one designed to detect if someone is trying to defeat it with a rouge magnet or one in the wrong location. There will be arrown on the case indicating where they need to line up and it wont have anything like the same tolerance of a grade 2 contact. Id also tidy up your wires there is too much exposed

-

Texecom Premier Elite - tamper alarm only when door contact is closed

ywu replied to ywu's topic in !!..DIY Installers..!!

Is there an issue with it being Grade 3? I have tested it on two sides of the sensor but it's the same issue. Perhaps it matters what the poles of the magnets are used? I haven't tried that yet. -

In preparation for my renovation, I detached the garage door contact sensor and the magnet, which as expected, caused a tamper alarm. The sensor has been put back together and my hope was, I'd bind the two together until the work is done in that area but what I'm finding is the control panel shows a tamper alert when the magnet is brought into proximity with the sensor. No fault is there when they are separated. What might be the issue? Here's what the sensor looks like inside.

-

ywu joined the community

-

Spoons watered down, you want Export.

-

Do they have JD Weatherspoons?

-

Nah I think they can get the proper stuff dude .....

-

Off thier tits on Halal Carlsberg ?

-

Party time in Iran apparently....

-

Lol

-

The president of Iran dead wrapped in a blanket- The bloke from verisure still appears to be trying to sign him up ?

- Earlier

-

chemical started following Having an alarm running on batteries is NOT a new idea

-

Paul Grant joined the community

-

Matthew Cheung joined the community

-

Thank you at last the first person on this site to actually know what I'm experiencing, this is exactly what I have researched over the last week! though I'm not sure dipping the 12V for 50ms is the best practice ? If this is by design I will see the same results on the new panel At least someone is in tune with the performance I am seeing on the elite 88 panel thank you

-

You need ? they all do a battery test, forget it man just install it and move on with life lol

-

Not at all ! I do struggle a little when your making accusations that are clearly not true? I do not assume anything, everything in my working life is a process of elimination when problem solving, I have eliminated everything with this alarm panel and the problem in hand and shipped it back to the supplier I have be appreciative of peoples feedback, but do no appreciate rude people or arrogance, I'm an embedded engineer and apply logic and common sense, I have listened and performed every test suggested along with many of my own and come to the conclusion the panel is generating the dip in the 12V every 30 seconds I am now at the stage that I would like to compare a brand new panel and see if I get the same results Once again thank you to everyone who has been kind enough to give their input and feedback without being rude ?

-

No I did not buy from ebay ? I have shipped original panel back to company and got a full refund I have spoken to another company they say they get there stock from Texecom every three weeks I have now purchased from them a new panel (Premier elite 88) with latest firmware Lets wait and see if this panel performs any different

-

reesehughes joined the community

-

al-yeti started following Verisure? Verypoor

-

Not wishing to get into the debate but 'Proper' gear needs to comply with the product standard (not the install) and part of that is testing the battery OK Most if not all panel will dip the supply and measure the voltage as a means to do this check. ie also all the 12v peripherals should be able (if compliant) to handle this ripple voltage. I dont know texecom gear well or at all and not sure if the network errors are a log tool or just log 'noise'. Either way it shouldnt cause a problem in normal operation. If it is causing a problem (other than a disganostic log) then something is wrong.

-

Congratulations on being our latest alarm expert & welcome to the moderation team....

-

Texecom Elite 88 Expander Errors

sixwheeledbeast replied to JOHNNYH's topic in Control Panels (Public)

For someone with all the kit and knowledge you seem to assume a lot, instead of diagnosing it. We may as well speak into the void at this point. Your repeating the same thing and clearly not reading or taking in what people are saying, your the one with the issue and looking for help... -

So all this means when you get a new alarm panel and you say it will be the same as the last one , you will be in the same boat ? Problem unresolved? You bought from eBay ?

-

your not listening, please take time to read and analyse before posting. the switch mode power supply is 100% stable, 13.6V rock solid !!, there is no switching noise, it would be a **** psu if there was lol, the network 12V every 30seconds produced a dip for 50ms as it switches to battery test mode, more than likely done by a FET by design !! Try doing some research you may find your elite panel is doing the same lol, though you would never know with your multi meter ? as I keep saying everting is working, 100% please stop saying my kit is not working, as it’s starting to sound infantile it’s very common knowledge from Texecom these elite panels operate in this way very surprised your not aware for having so many years with Texecom alarms systems ????

-

Who's Online 1 Member, 0 Anonymous, 184 Guests (See full list)

-

Member Statistics

-

Forum Statistics

33.2k

Total Topics443.7k

Total Posts