-

Posts

292 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Downloads

Gallery

Blogs

Posts posted by Gabs

-

-

17 hours ago, MrHappy said:

I was toying with moving over to these-

These are the small speaker the large speaker ones haven't turned up yet

In the flesh they not any smaller in profile than normal speaker

https://www.knightfireandsecurity.com/product/grade-3-internal-sounder-octone/

However starting small with something like the above would still be a significant project...

Thanks for that, well, everyone has to start somewhere. I am still looking for an idea, or something I can make, which will be an improvement to the security or electronic industry

-

30 minutes ago, MrHappy said:

@gabs an extension speaker in its basic form is just a speaker in a box

You need to have mould made & could use a 3rd party to produce a run of plastics

Speakers would be bought in, production would be putting leads on ect... assembly & packing

As a hobby you'd probably cover your costs... As a business you'd probably loose money

I understand that, I definitely wouldn't want to loose money, you got any ideas or suggestions? Want to get into manufacturing

-

8 hours ago, GalaxyGuy said:

Having designed compatible modules, my thoughts for panel / module / sensor design would be to leverage other modules/sensors that are out there already. If you have no experience in firmware and electronic design, then the more complex parts of the system will be a huge undertaking.

I would expect a control panel alone (enclosure / electronics / firmware / software / compliance / packaging) at current market level product expectations to take at least 100 man months of effort to go through concept, alpha, beta, release and ramp to volume.

To release a product within a couple of years would mean recruiting skilled engineers and probably cost in excess of 500k. The volume sales required to recover the development costs are huge, so risk is very high. There's also ongoing support costs, as nobody wants to buy a product that has no long term support. Any investor willing to back such a venture would be looking at your own track record, your own investment and ability to bring it all together.

As others have commented, it's probably best to start very small before even thinking about something complex. The internal speaker is a good example. Take all current offerings, perform teardown analysis, voice of customer analysis and so on. Design something new. Send out free samples. Get feedback and iterate until you have an ace product that your customers want.

That said, it's still very difficult to produce something simple and make money. You may be able to design with a small team (ie.yourself) in the UK, but would find it very difficult to make profit manufacturing here. It's all a very nice thought of being able to create local jobs for people, but very difficult to justify if skilled/unskilled labour is available at 1/5 of the cost elsewhere.

Thank you GalaxyGuy, didn't think o the ongoing support that would be needed. Starting small, I could buy internal sounder speakers, and create my own siren driver circuit put that in, and sell it as a siren with the tamper added. That may be a good start. The shed alarm idea I had I am still working on. I will look at the engineer prices, although I can image they would be high.

4 hours ago, PeterJames said:Not necessarily there are temperature and humidity detectors available separately, there is no panel that could collate that info and adjust to the environment

I would like to design a PIR that can be used anywhere with no false alarms, however the problem is it couldn't be used on the standard 6 core cable configuration, or be used with any panel, e.g.

Texecom Medusa PIR will work with an ADE Optima XM

I could produce those bell box dummy LED modules, do you professionals use them?

-

14 minutes ago, PeterJames said:

Features:

Nobody makes an alarm with a decent chime noise anymore (I liked the 9100 chime and the DA chime)

Variable EOL settings, making panel changeovers a doddle

Onboard intelligent analytics, a panel that can make decisions based on environmental detection inputs.

If I do go into the panel ,manufacture further, ill take note of these. The chime one is good. Environmental detection inputs?

2 minutes ago, MrHappy said:to set up manufacturing you'd go to a venture captial co.

However I'd assume CSL have made lots more £ than any panel maker ever has & there a "marketing co." ?

I will look into this too, CSL?

-

11 minutes ago, MrHappy said:

Produce a pp3 power standalone shock sensor like we used to buy in the early 90's

Produce commercial controls which network together rather than panels & expanders ?

Produce an 8 zone wire panel with onboard keys, which is nice & slim cuase it got a NiMH battery

There loads of stuff which could be made, the hard part would be making money

I agree and even harder getting the money to do it in the first place, only thing I can think is a bank loan? However, if it was successful, it would end very well, for person starting the company and the products being made would be better.

-

14 minutes ago, MrHappy said:

If I was insane enough to get involved in the manufacture of alarm stuff-

Happytronic would import cheap & cheerful tat from the far east, say sounders or lead acid batteries

if this proved to be successful the most simple product to start in house manufacture would be an tampered extension speaker,

I suspect creating a commercially successfully alarm panel manufacturer from nothing is very hard ...

Thanks, making things in China would be cheaper, but making stuff here is good too, I am NO Brexiteer, but this it employs people here so that is good, but buying things from there cheaply is good. Yes, it might be hard, although I do want to start a company, could start an eBay business I guess, selling those dummy LED modules.

-

22 minutes ago, MrHappy said:

I'd also assume if you had the ability to produce intruder alarm controls you would make a lot more doing something different ?

What else could be produced, I can see the main things needed for a panel could be injection moulding facility and a PCB manufacturing machine?

-

So your alarms were made in house? rather than using separate companies to make them?

-

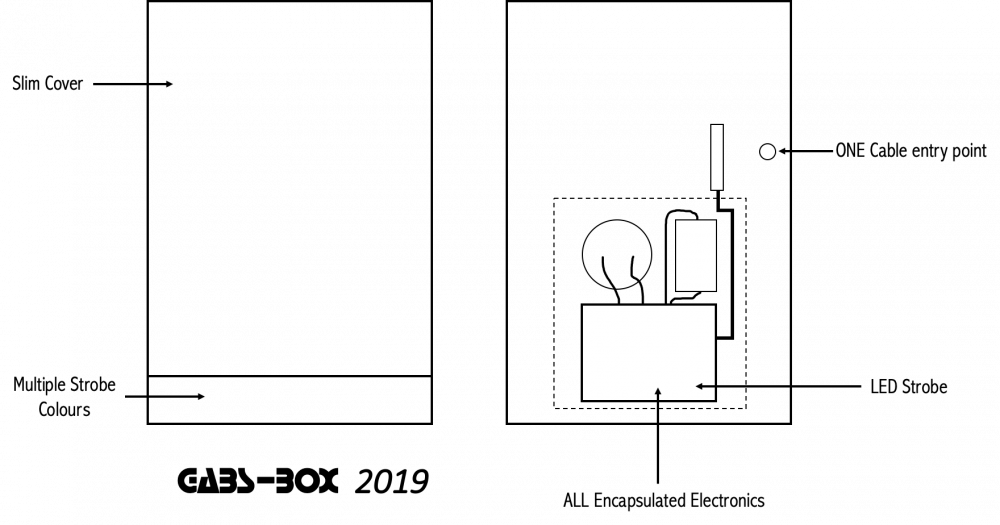

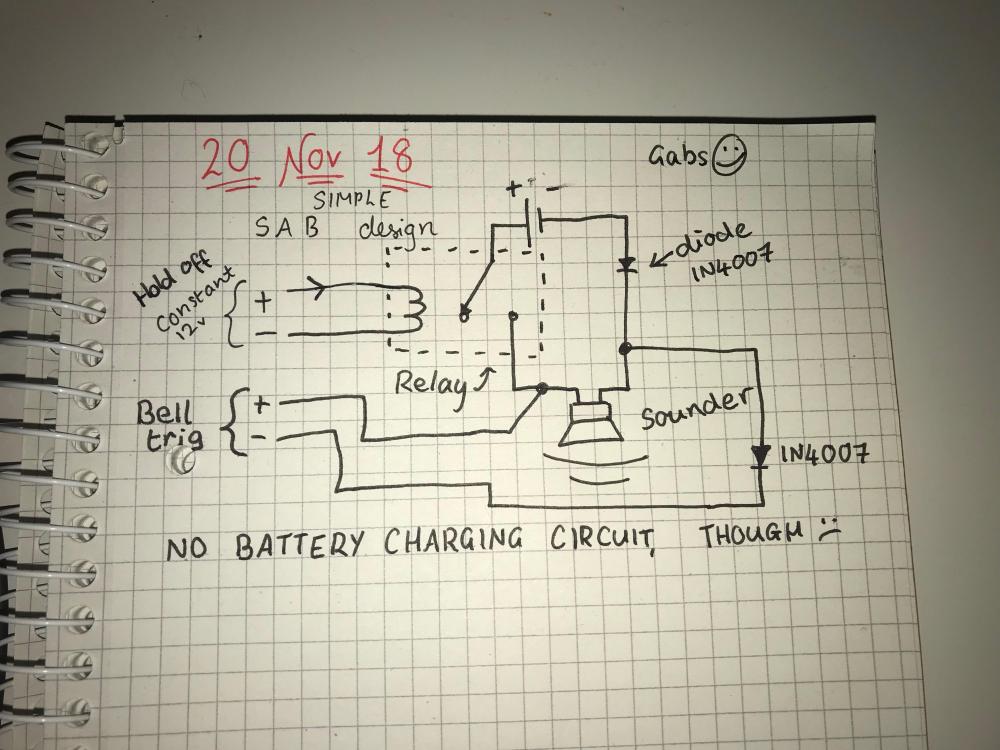

Thanks for the replies, a basic design I had for a bell box was this:

I would like to think that it has been designed well with encapsulated or even potted electronics, designed for any weather or condition. I could look at making a bell box or shed alarm first? Before trying a full main control panel?

-

Thanks for the replies, I know about all the British Standards, been looking into them and seeing what my Accenta G4 (Newest one) complies with. What features would you like? I know I would want something that has a discreet keypad which isn't ugly or big, that blends in and isn't made of cheap plastic that'll just yellow. Same for a bell box, id design an ultra slim SAB, which is made from decent plastic.

Hopefully AlYeti will stumble across this post and can give me an insight into the process, who are DA?

-

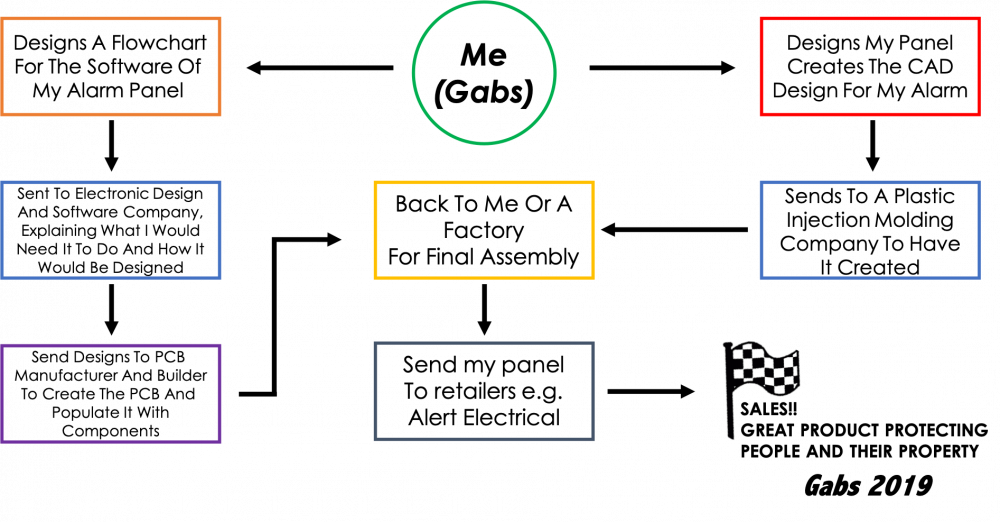

Any Help, comments or even criticisms are appreciated. If I wanted to start a company, to put my product idea into the market, how would I go about this, employing minimal people. Please see my basic structure below.. I do have a few unique ideas, which I think would really catch on, not just panels. And, is this how companies like ADE, Texecom and Pyronix do/did it? Or was it all done in house? No separate manufacturers

-

@MrHappy Treat Yourself https://www.amazon.co.uk/Hantek-DSO5102P-Digital-Oscilloscope-Real-Time/dp/B00I5EWF1U/ref=pd_sbs_263_1?_encoding=UTF8&pd_rd_i=B00I5EWF1U&pd_rd_r=9259545f-0aef-11e9-84e9-0f828c410421&pd_rd_w=7sYyD&pd_rd_wg=cH6IT&pf_rd_p=18edf98b-139a-41ee-bb40-d725dd59d1d3&pf_rd_r=H994SW1EBCCXA65WKYB1&psc=1&refRID=H994SW1EBCCXA65WKYB1 Really good to have, even if it is for looking at the secret language of the Accenta

-

2 hours ago, MrHappy said:

I'm just impressed @Gabs has scope that's worth a good 10x the price of new "ade" controls

Thanks, glad you like it, its a handy thing to have

I am after an Accenta G4 Actually, don't have one in the collection... Although, it isn't real ADE

I am after an Accenta G4 Actually, don't have one in the collection... Although, it isn't real ADE

-

3 hours ago, sixwheeledbeast said:

All systems are different, manufacturers will have there own protocols to suit there kit.

Galaxy is a standard 485 bus for example, some maybe clock and data or Wiegand derived like the majority of access control, there are many more ways it's all down to the manufacturer.

I suppose I have a fairly broad knowledge of a few things computing and electronics being one, some from school and college but a lot self taught. They have always my thing.

Back in the days of C&G 1851, data transmission methods where part of the security system exam, not sure if this is still the case.

I certainly have never done anything near a professional layout or designed panel but built a good few different circuits on stripboard in my time.

What you can learn now with the relative cost of SBC's like Arduino and RPi is a lot more is based on GPIO and code, over the logic with discretes and IC's that I started on.

I can only suggest you start basic adding functionality as you go on, if that be in logic gates or whatever code you choose.

Make a sensor trigger a sounder. Then make able to be armed and disarmed. Then eventually work up to security of the transmission and tamper protection.

Here is a link you may find useful about the way a keypad would work from my post above for example http://www.circuitbasics.com/how-to-set-up-a-keypad-on-an-arduino/

As you can see the computing power of an SBC is many times greater that of the Accenta you have on the bench so it's quite different practically.

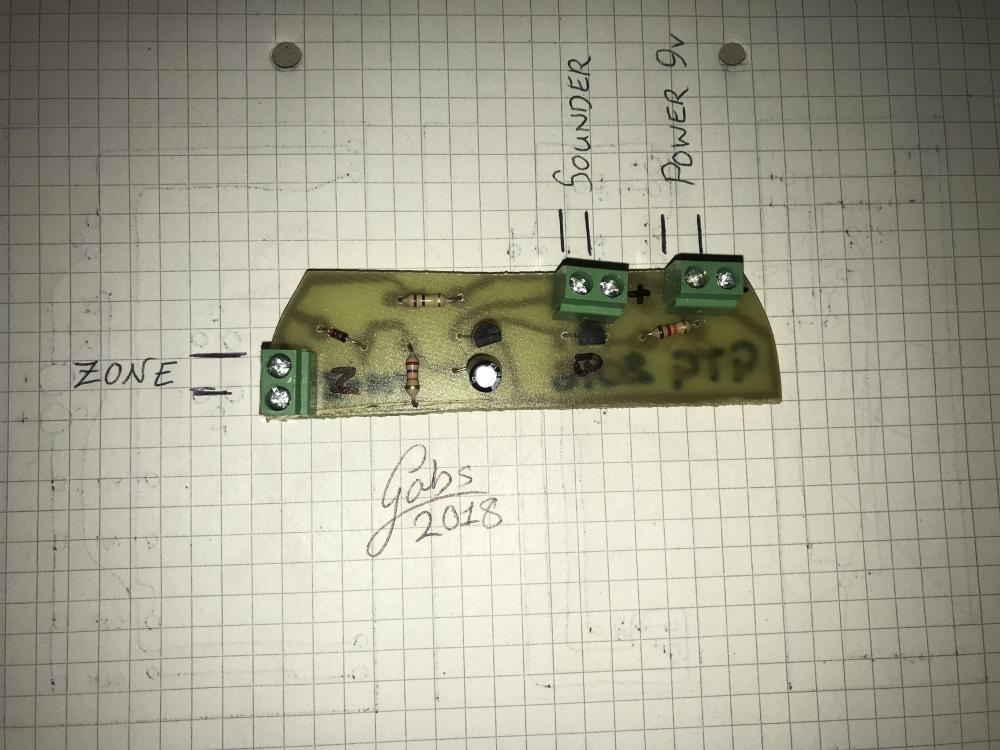

Thanks, I was going to start by making a key-switch panel, based around a microprocessor. I have made one around transistors before:

This was on a hand etched board, that I made. I used a paint marker to draw on the tracks, for all of the components. I will have a look at the site though. I have some CMOS chips, I may use to make an alarm, to panel. I made some bell box comfort LEDs swell, this way. I like the rewarding feeling of building circuits. The circuit pictured above is. A very basic transistor latch, it would need a relay to be able to switch any decent siren on, however its correct draw is practically zero. I was thinking of trying to mimmic the Accenta's keypunches of 4 and 9 (SOS) with an Arduino, this would be a good way of testing if I can use my own. Do you know what type or brand of microprocessor is used in most alarm panels, PIC or ATMEL. I think the Accenta has a Pic Microcontrollers but not sure, the NVM chip can't be found on the G3, so it may be held in the microprocessor.

-

1 hour ago, sixwheeledbeast said:

Ah yes you are correct about the tamper loop, although the theory is still correct.

Have a look into NRZ serial transmission for other benefits of having the line high all the time.

Also think about what could happen if there was an intermittent short on the multi cored cable for example.

Transmitting decimal numbers via a type of pulsing binary is very inefficient. Your too young to remember how long it took to dial 999 on a pulse phone...

You can send a hex value in a nibble, for example this would cover all 15 keys no problem, but imagine an easier ways using rows and columns which keypads generally are.

As an example, divide your keypad into col (1-3) and row (1-5). that's 3x5 each axis (We will start counting at 1 here not 0). Send binary X, binary Y and a check and/or stop bit, all can be done with binary in a bytes worth of data.

Key 0 001 001 1 0 Key 1 001 010 1 0 ... key 7 010 011 0 1 ... Key Prog 011 100 0 1 Key Set 011 101 1 0All the keys would be sent in the same amount of time as sending an 8 via pulse.

Using BCD you could likely make that smaller again, the lesser amount of bits needed to transmit to get the message over the quicker the communication.

Thanks for the reply, reason for me asking all this is that I am going to have a go at building my own panel, baed around an Arduino board: https://en.wikipedia.org/wiki/Arduino

I will have a look at that type of serial transmission, hopefully I can have a go at programming something to recognise it. I can see a problem with the speed and efficiency, according to my oscilloscope, when pressed, the keypad sends the data out in a burst that lasts only 24 ms in total, so very fast. Do you know if all alarm panels use this method? Or is it just ADE panels? WHere have you gotten your knowledge on this from, did you design alarm panels at one time?

Thanks,

Gabs

-

1 hour ago, sixwheeledbeast said:

Having never attacked an Accenta with a scope before I am just theorising, however...

On a Accenta you have one signal line for data transmission therefore the transmission is serial.

As you say there are no separate Clock and Data lines to avoid data collision but what's to say a single non-zero return (NRZ) signal cannot be two way?

You could still transfer signals asymmetrically, maybe down to encoding for example, you could have a stop (handover) bit. The last bit on the scope images seems similar so this maybe the handshake bit for the reply or even the actual handover of the supply.

Both will need the ability to drive 5V signals to each other, although I would imagine the keypad will supply it most of the time. That way if the voltage is missing (hence using NRZ) for a period of time the keypad could be declined offline and tampered.

If you think about it these non-LCD basic alarm keypads are fairly dumb, they sit and wait for input so in most cases the messages to be sent towards the panel are call and response (the response changing/updating the display with data from panel).

The only time the panel would need to call the keypad into action (send data the keypads way) would be in an alarm situation, hmm I wonder what that sound wire could also be used for...

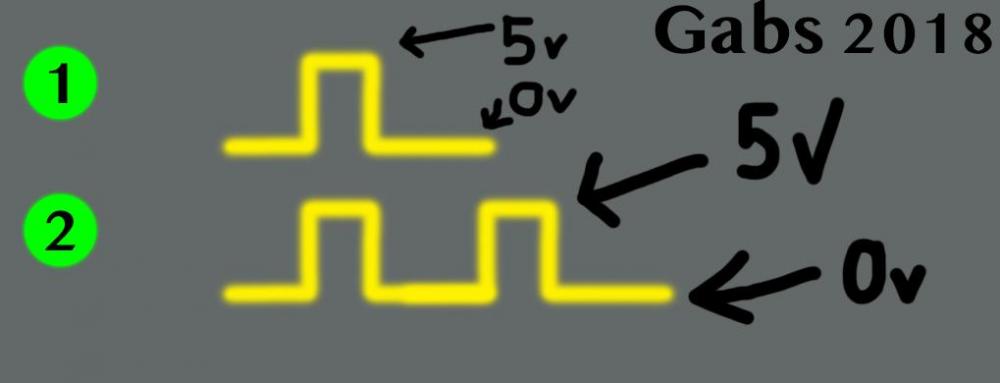

Wow, thanks for the reply, think I understand it

I understand that, but still am unsure how the keypad can drop the 5v that the panel is sending it, when a button is pushed. I would have thought that the Comms was always at 0v, and would only become active with 5v when a button is pushed, the Accenta has a different Tamper loop, with the comms disconnected, but everything else left in place, none of the keypad buttons work, as it is only this line the signal is send down. I have an early Accenta LCD keypad, and it works with his panel, using exactly the same drops in voltage, so it can recognise them and then displays vague messages on the screen, not as good as the G4 one. If I was designing an alarm, I'd have made it like this, If one or 2 were pressed, then the button number would correspond with the number of 5V Square waves are sent. Can you think of any reason, the ADE didn't do it like this? Or have any alarm manufacturers done it like this?

I understand that, but still am unsure how the keypad can drop the 5v that the panel is sending it, when a button is pushed. I would have thought that the Comms was always at 0v, and would only become active with 5v when a button is pushed, the Accenta has a different Tamper loop, with the comms disconnected, but everything else left in place, none of the keypad buttons work, as it is only this line the signal is send down. I have an early Accenta LCD keypad, and it works with his panel, using exactly the same drops in voltage, so it can recognise them and then displays vague messages on the screen, not as good as the G4 one. If I was designing an alarm, I'd have made it like this, If one or 2 were pressed, then the button number would correspond with the number of 5V Square waves are sent. Can you think of any reason, the ADE didn't do it like this? Or have any alarm manufacturers done it like this?

Thanks,

Gabs

-

ANY HELP IS GREATLY APPRECIATED

Would anyone be able to help me in finding out how a keypad talks to the main panel, I have an oscilloscope asd I have connected it to the 'Comms' wire, when the Accenta keypad is connected to the panel. This wire is at a constant 5 volts, with dips in this voltage when a button is pressed, or the panel needs to send the keypad information.

This first image shows the data line between the panel and keypad when 1 has been pressed, these dips in the 5 volt signal were created by the keypad, for the panel to recognise.

The above image shows what happens when the 'PROG' key is pressed. The highlighted in red waveform is the keypad sending the Prog signal to the panel, the one in green is the panel responding to the keypad telling it to light up all LEDs.

What I do not understand is how the keypad can create a dip in the 5v line if the panel is constantly giving out 5v, same with the panel, how can it then create a drop in the voltage in the data line, if the keypad is constantly giving out 5v. The only way I thought it could be done was the panel shorts out the keypads data line, and the same with the keypad, it shorts out the 5v of the keypad to create 0v in the 2 way data line. Just wondering if this is correct? If anyone knows. I have tried the sound line, however it doesn't carry any data, just 'beeps' and alarm tones.

-

8 minutes ago, MrHappy said:

Shame it is out of stock. Looks quite advanced for one. I will just have to try trial and error for my design, I have one, but it would only be one time use, as it wouldn't be charged up again

-

7 minutes ago, MrHappy said:

Four core &

+

_

Tamper Return

- Bell Trigger

Would have how the Module would have been fitted back in the 80's ?

Might have been, taken any of them down recently? I would try to design the circuit like that, just don't want to damage my panel, if it goes wrong. I have built a few Security-Related circuits recently, Don't know anywhere that would sell old stock SABs

-

3 minutes ago, sixwheeledbeast said:

Most alarms send a -ve back to the panel via a microswitch (hence the phrase "tamper return").

Either way IMO it would make sense for the field wiring to terminate to the PCB (for service and fitting reasons) even if you are just soldering a microswitch off the back.

I will just do that, then. I can solder one straight to the board. The dilemma still lies in the battery charging circuit, I think a 1 watt resistor would do, constantly powering the battery until it is needed, that is why ideally I have an SAB module to copy the circuit from, and understand how it would be charged. Was going to see if I could get it to work with this, once I have built it

http://www.zen22142.zen.co.uk/ronj/sh.html

http://www.zen22142.zen.co.uk/ronj/sh.html

-

11 minutes ago, sixwheeledbeast said:

So no anti-tamper protection?

The idea was just for a microswitch to go straight to to SCB of my Accenta panel, I could route it through my SAB module, but it would just be two tracks, from one terminal block to another. Could be done with standard 6 core wire, too.

2 for the Tamper

2 for the Hold Off voltage

2 for the Siren

-

18 hours ago, sixwheeledbeast said:

Would normally be a single -ve applied for the trig.

I was going to do that, butt thought it would be a little easier to use the + and -, I could keep everything positively charged inc the siren, and then I would be able to make it a neg trigger, but since I have terminal block in sets of 2, the full on + and - should do, just use an extra core.

18 hours ago, MrHappy said:never seen anything or heard of this co. before, however

01297445 REVDUN ELECTRONICS LIMITED Dissolved 22/05/1993

01907384 REVDUN SECURITY PRODUCTS LTD. Dissolved 06/11/1990Google throws up your topic on here about a panel & a linkdin page which say they where in Birmingham ?

I remember that, it works with the panel, which I still have. It is good, for an early panel, all hand-etched boards in it

-

-

6 minutes ago, sixwheeledbeast said:

Possibly an SCB, from looking at the traces in the photos.

Battery negative runs into the contact of the relay?

Says Leyland on the buses but they don't all go there...

Yeah, that is correct, the negative of the battery goes into the relay. It would be very easy to make a bell module with no charging circuit, you'd only need a relay. Board looks hand-etched too. And it could be SCB, it is powering a bell, not an electronic siren, so I can't imagine that battery lasting long anyway. It amazingly still holds a charge.

Start An Alarm Manufacturer

in Members Lounge (Public)

Posted

Is this something that you designed and implemented? it is a good idea, and would reduce false alarms.