-

Posts

90 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Downloads

Gallery

Blogs

Posts posted by spike27

-

-

On 7/31/2017 at 17:05, MrHappy said:

ita the alloy which is appearing to rot away much quicker than in the past ?

Thanks for this. I will make some enquiries.

-

On 2/14/2017 at 22:17, MrHappy said:

I use Knights RSC, they appear to got rotten & fail much quick than they used to,

Hi MrHappy. I will ask if we've changed the resin / compound used to seal the units recently and update the thread when I get an answer back.

-

Bit late to the thread so apologies, but a few years back we did have issues on our G3 RSC (YF10C). They would be tested with a meter successfully pre-install, tested in situ successfully, then commissioned and handed over successfully. Yet a random period later, they have gone into tamper (usually at 3am). Cue phone calls to us, site visits (150 separate loading bays in large Distribution Depot) to inspect but no visible damage and RSC working perfectly well leading to much scratching of heads.

Turned out that some of the concrete bays were steel reinforced (buried in concrete so not visible) and the Magnetic Interference Detection was being triggered due to natural variations in the magnetic field. This led to the design, manufacture and supply of the 10mm thick rubber spacer in the video below. This has alleviated every instance of this problem.

-

11 minutes ago, datadiffusion said:

No not tried them for a while, I have quite a few older ones which I've been saving up for my own place where speed and ease of installation is less of an issue...

Fair point. As we managed to cram in so many different panel options / double door config / TACT tamper and MID for G3 , the orientation of the arrowed resistor modules can be a little fiddly. Although they are shipped out as Galaxy config by default, if that helps...

-

On 08/10/2016 at 2:33 PM, datadiffusion said:

Yep when it comes to flush I still rate elmdene better than Knight, who I use for everything else.

for the feedback! Don't know if you've tried our G2 and G3 flush multi's recently, but we've now thinned the fixing plates down to 1mm after installer input.

for the feedback! Don't know if you've tried our G2 and G3 flush multi's recently, but we've now thinned the fixing plates down to 1mm after installer input.

-

Really sorry to hear that. He was the poster I most associated with this forum. RIP

-

2

2

-

-

14 hours ago, Danny May said:

They look good, but horrible to

imstall... the lids are flimsy!

Have you tried them recently? We strengthened the lid clips and slots after negative feedback around 12 mths ago so you should see an improvement.

-

Our G3 'Soapdish' speaker is a perennial favourite, presumably for its sleek lines and unobtrusive aesthetics

http://www.knightfireandsecurity.com/view_item.asp?id=46

-

It was down to me that you or your design team come up with that diagram as you had **** all before, you had to bench test and get back to me.

I believe it was then uploaded on your website - so i was told from your end.

Plus point, the lad i dealt with was spot on, i even sent a thank you email the day after.

Off the top of my head, it may have been yend 24, i can check if need be.

Whats that supposed to mean?

IIRC it was yend 24 and the yend 75 terminations are different.

Hi Adi - we did have a multi drawing but it was discovered (after your call) that it didn't correlate perfectly to a later revision of the PCB shared zone jumpers! So yes, you did indeed alert us to this anomaly, so thanks for that

:'>

:'>Also, my Technical colleague here saw your comments above and said for me to say thanks for the positive feedback!

Any further queries from you or any other posters are welcome on here, good and bad as it helps us improve!

-

I have installed a Knight Industrial magnetic door contact on a sliding patio door connected to a Galaxy Flex 50. It's been working fine for a few weeks and in the last week Ive had a couple of false alarms from the contact. First time round I looked at the panel diagnostics and was seeing the resistance fluctuate a little between 1000-1100ohms while closed. I took the contact apart, reconnected and things looked like they had settled down fine. Last night it went off at 2am.. so I disabled the contact. Today I set it to log and chime, and sure enough it went off later in the afternoon and on looking at the diags it stayed open at around 1500ohms (obviously while the door was still closed). I gave the contact a small tap and it dropped back to around 1000ohms. Is it still likely to be a duff connection, or is it a faulty contact? I did notice that when the door is pulled shut hard the contacts do slightly/momentarily knock together, should I open up the gap between contacts also?

Hi Neil,

Not sure if this is resolved, but in any case could I ask which partcode you were using to try to ascertain the issue? It does seem likely that the contacts were too close and the knocking together is affecting the delicate reed inside (albeit momentarily but enough to create an alarm / tamper).

-

i wired 4 knights eol on one zone last week (2 sets of fire doors, linking 2 zones together in the control panel) fun and games were had then, never again.

Would have been cheaper for me to buy an expander.

You don't state which contacts you used on that installation but for future reference, our G3+G2 YEND74 and G2 D75MULTI are specifically designed for multi contact configurations, as detailed in the diagram below:

-

Ah possibly, I know one replaced another

Hello all. Bit late to see this, but the D75MULTI is an addition to our range i.e. it didn't replace anything. The YEND74 is one of our most popular contacts and is predominantly used as G3, but also contains a header to bypass the Magnetic Interference Detection thus making it suitable for G2 also, thus reducing van stock / distributor storage space required.

The D75 is for those who want to add their own resistors - the D75MULTI comes complete with resistors (both obviously cheaper than the YEND74). All of these products contain 2 free spacers in each pack.

-

Thought it might be two whites Spike, those were the usual colours at one time, nice post you've made.

Yes, you were right Charlie. And thanks for the condiment

-

Posted this in wrong thread earlier, so here it is again:

-

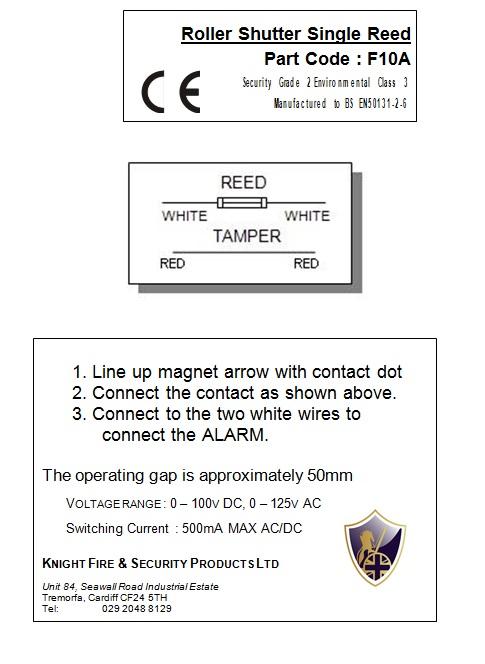

Below is a screenshot of our non-resistored RSC install sheet for your reference:

Unfortunately, I posted this in the wrong thread so if the mods would like to remove it then feel free.

-

Below is a screenshot of our non-resistored RSC install sheet for your reference:

-

hopefully after a yr "hapoychappy" has either figured it out or given in

An excellent point, well made

An excellent point, well made *note to self - check installer forum more often*

-

Just noticed that you mentioned 2 reds and 2 whites in your OP, which actually suggests you have our unresistored F10A / F10C there. The install sheet is available at the link below:

http://www.knightfireandsecurity.com/uploads/F10A%20Inst%20Mini.doc

-

Interesting to note. Will log this for any future tech queries we get along these lines,

.

. -

Wanting to install some door contacts on a galaxy 2 Honeywell system any1 got an suggestions on any good ones needs to be 1k resistance either side

im thinking elmdene ones but thery're 400Ohms over would this cause any problems?

Not sure what EN50131 grade system this is but we have loads of options for you, inlcuding selectable resistors for all the main UK panels in one product on our preresistored products (i.e. not 'colour' or 'Type' coded for different panels) plus ours have generous operating gaps and are suitable for use on double doors / shared zones / wired in series:

Grade 2 surface contacts:

http://www.knightfireandsecurity.com/catalogue.asp?id=21

G3 surface contacts:

-

Well, I've heard that Knight use only EU or US made ones, I assume Elmdene buy 'locally' in China as they manufacture over there, and Ventcroft I can only guess must have bought a really sh1tty batch from god knows where.

I have never had a door contact fail like that before, an RSD yes, although that wasn't welded shut that was random opening.

This is correct datadiffusion. We only use UK sourced reeds in our products, from Hamlin and Standex. These high quality components may cost more than the foreign manufacturers, but we keep costs down through efficient mass manufacturing and our other strength over our competitiors is that all of ours are manufactured and assembled here in the UK. I remember seeing a competitors' packaging which clearly states 'Made in China'...

Even with the highest quality however, the nature and fragility of the reeds themselves means that they need very careful handling from receipt by us right through to installation and maintenance.

Despite the tightest QA procedures involving testing every product before they’re shipped, there are always a tiny number that somehow arrive on site in a faulty condition. The nature of the reeds inside means that an invisible crack can test ok at the factory, but as the sealed gas slowly seeps out, it becomes faulty before or even months after install / handover.

As a company we always ask for any faulty units to be returned so we can test them to see what went wrong. We also offer a no quibble replacement arrangement (either through your distributor or direct through us). Unfortunately, as they are often the lowest cost part of the system, they're often binned so we never find out

(

(Of those that do report back however, we respond very quickly.

-

Hi Happychappy,

Sounds like you either have our F10CMULTI (G2) or our YF10C (G3).

Both product web links are listed below fyi, and each of those contains downloadable install sheets which will show you the colours you need to connect to get this baby firing:

F10CMULTI:

http://www.knightfireandsecurity.com/view_item.asp?id=331

YF10C:

http://www.knightfireandsecurity.com/view_item.asp?id=279

-

And more to the point, anyone with half an ounce of brain, should be able to figure something as basic as that.....surely?.

I thought the same a few years ago but you'd be surprised (no, make that horrified) to hear some of the questions to our technical line...

-

sorry, which panel, what grade etc .......... and any chance of a drawing how you intend to do it?

Just spotted this and whilst I'm sure this has been resolved by now

our F10CMULTI (G2) is suitable to be wired two to a zone, as is our YF10C (G3). Sections of wiring diagrams below (full diagrams available for download at the links):

our F10CMULTI (G2) is suitable to be wired two to a zone, as is our YF10C (G3). Sections of wiring diagrams below (full diagrams available for download at the links):F10CMULTI:

http://www.knightfireandsecurity.com/uploads/F10C%20multi%20%20inst%20001.doc

YF10C:

http://www.knightfireandsecurity.com/uploads/YF10Cii%20rev2.pdf

for the feedback! Don't know if you've tried our G2 and G3 flush multi's recently, but we've now thinned the fixing plates down to 1mm after installer input.

for the feedback! Don't know if you've tried our G2 and G3 flush multi's recently, but we've now thinned the fixing plates down to 1mm after installer input.

:'>

:'>

Euro 46 app panel

in Members Lounge (Public)

Posted

New link to our ever popular Grade 3 surface contact YEND74 below:

http://www.knightfireandsecurity.com/product/grade-3-surface-contact-suitable-for-double-doors-with-mid-suits-all-panels-white/